4 Things Industry 4.0 10/13/2025

Presented by

Happy October 13th, Industry 4.0!

The gap between "playing with AI" and "shipping with AI" is closing fast. This week brings us tools that turn experimental workflows into production systems—from Claude that can actually do things via Docker's MCP Toolkit, to infrastructure you can request in plain English with Spacelift Intent.

Meanwhile, Bun 1.3 is making JavaScript feel like a real full-stack runtime, and the industry is waking up to the difference between "vibe coding" (throwing prompts at a wall -- we know, Walker hates that word) and "vibe engineering" (using AI responsibly to ship faster).

The future isn't just AI-assisted anymore. It's AI-integrated, AI-grounded, and ready for production.

Grab your coffee—we're bridging the hype gap.

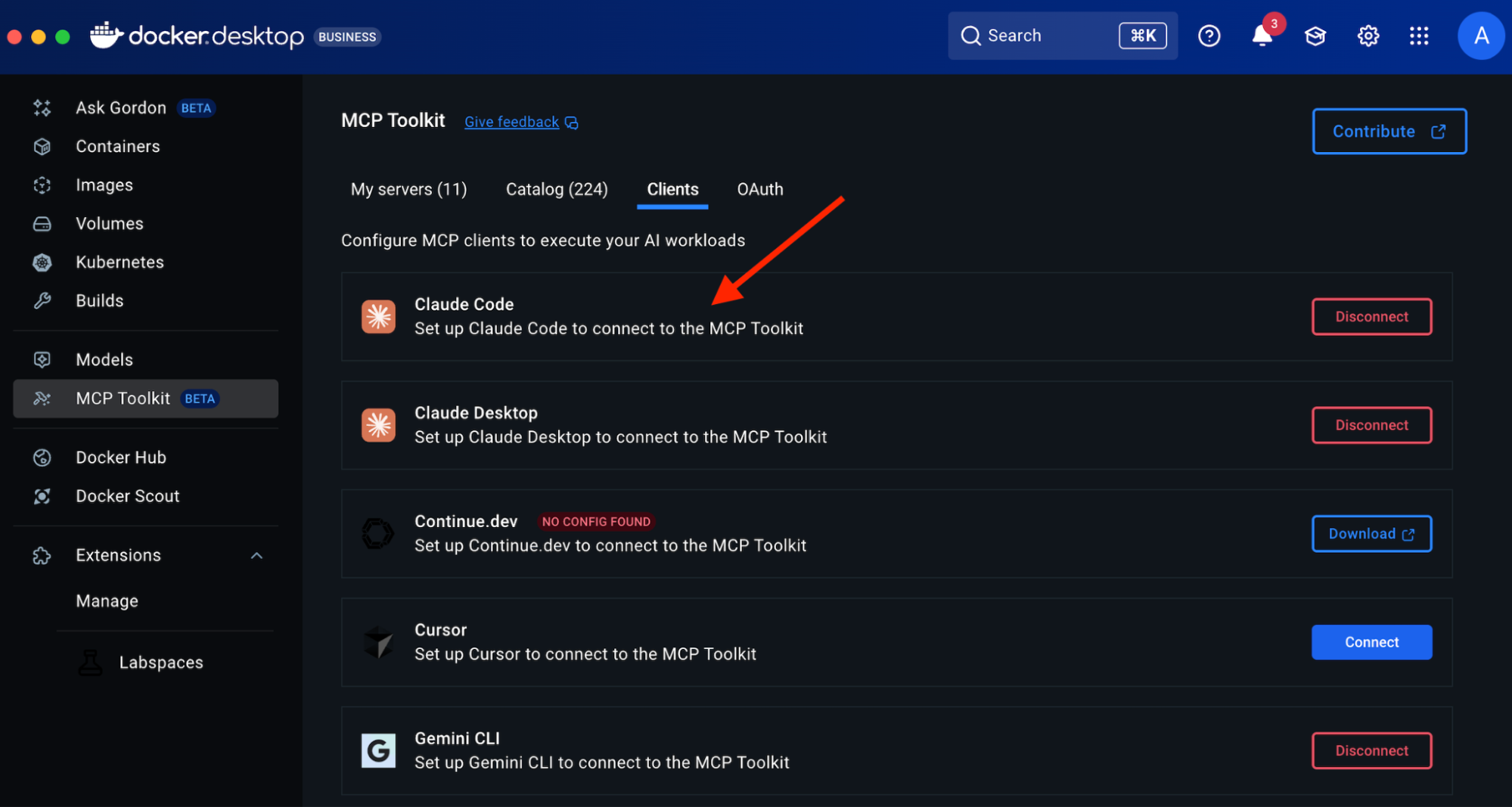

Docker MCP Toolkit: Claude Code Meets Real Development Tools

Docker just made Claude Code exponentially more useful. The new MCP Toolkit connects Claude to actual development environments—letting it run database queries, create GitHub issues, send Slack messages, and interact with over 200 pre-built containerized MCP servers.

Here's why it matters: Until now, using Claude Code meant a lot of manual copy-pasting and context-switching. You'd ask Claude to generate a query, then copy it to your terminal. You'd get code suggestions, then manually create the GitHub issue. It was helpful, but not integrated.

The Docker MCP Toolkit changes that architecture entirely:

- One-click deployment in Docker Desktop

- Automatic credential handling for secure connections

- Real-time interaction with databases, APIs, and services

- Pre-built servers for the tools you already use

Think of it as giving Claude hands to work in your actual development environment, not just eyes to read code. You can now have Claude query your production database, analyze the results, suggest schema changes, and create a pull request—all without leaving the conversation.

For manufacturers building custom tooling or analytics dashboards, this is huge. Your operations team can now have conversational access to your data warehouse, your Unified Namespace, your time-series databases—all through Claude, all with proper authentication and security.

The Model Context Protocol keeps proving it's not just a clever idea—it's becoming the plumbing for the next generation of connected, AI-native workflows.

👉 Read more about Docker MCP Toolkit

Spacelift Intent: Infrastructure as Conversation

"Can you spin up a Kubernetes cluster with autoscaling for our new sensor data pipeline?"

That's not a question for an engineer anymore. With Spacelift Intent, it's a request you can make in natural language—and get real infrastructure back, with governance, traceability, and exportability.

Spacelift's new Intent system represents a fundamental shift in how we think about infrastructure management:

- Natural language requests instead of HCL or YAML

- Built on OpenTofu and open standards

- Integrated through Model Context Protocol (yes, MCP again)

- Real infrastructure, not mock-ups or placeholders

The key insight here: Intent isn't replacing Terraform or OpenTofu for complex infrastructure. It's complementing them by lowering the barrier to entry for common requests while maintaining the same standards for safety and compliance.

For industrial applications, this could be transformative. Imagine your plant manager requesting a new analytics environment for a production line: "I need a dashboard for Line 4 that pulls data from our MQTT broker and stores it for 90 days with hourly aggregations."

Intent can translate that into actual infrastructure—compute instances, databases, storage policies, network rules—while your platform team maintains control over security policies, cost guardrails, and architectural standards.

It's the difference between gatekeeping infrastructure and enabling it. The request stays in natural language, but the output is production-ready, governed, and fully traceable.

This is what democratization of tech actually looks like—not dumbing it down, but making expertise more accessible.

👉 Learn about Spacelift Intent

Bun 1.3: JavaScript Goes Full-Stack

Bun just graduated from "interesting Node alternative" to "batteries-included full-stack runtime."

Version 1.3 is a massive update that includes:

- Full-stack dev server with hot reloading

- Built-in database clients for MySQL and Redis

- Improved HTTP ergonomics for cleaner API code

- VS Code integration with concurrent tests and type testing

- Better security with Bun.secrets for encrypted credentials and CSRF protection

Why should manufacturers care about JavaScript runtime wars? Because the tools you use to build internal dashboards, operator interfaces, and data visualization platforms just got significantly better.

Bun's speed advantage over Node.js is real—we're talking 2-4x faster startup times and significantly lower memory usage. For edge deployments or resource-constrained environments (like plant-floor HMIs or edge gateways), that performance delta matters.

But the bigger story is the developer experience. Bun 1.3 includes everything you need to build a production web app: database connections, authentication, testing, debugging. No more hunting for packages or dealing with version conflicts. It's all there, it all works together, and it's fast.

For teams building custom Industry 4.0 applications—whether that's a real-time production dashboard, a maintenance scheduling tool, or an operator training platform—Bun 1.3 means you can move from idea to deployment faster, with less friction, and fewer dependencies.

The JavaScript ecosystem just got a lot more serious about competing with Go, Rust, and other "systems-level" languages. And for web-based industrial applications, that's excellent news.

👉 Explore Bun 1.3

Sponsor Message

MaestroHub is a next-generation industrial data platform enabling manufacturers to unify, contextualize, and orchestrate their operations data. Founded in Turkey with a growing global presence, MaestroHub bridges OT and IT environments through a Unified Namespace (UNS)-based approach, empowering companies to reduce costs, optimize energy use, and improve yield. MaestroHub provides a scalable solution for both mid-sized facilities and large enterprises. Learn More Here: https://maestrohub.com

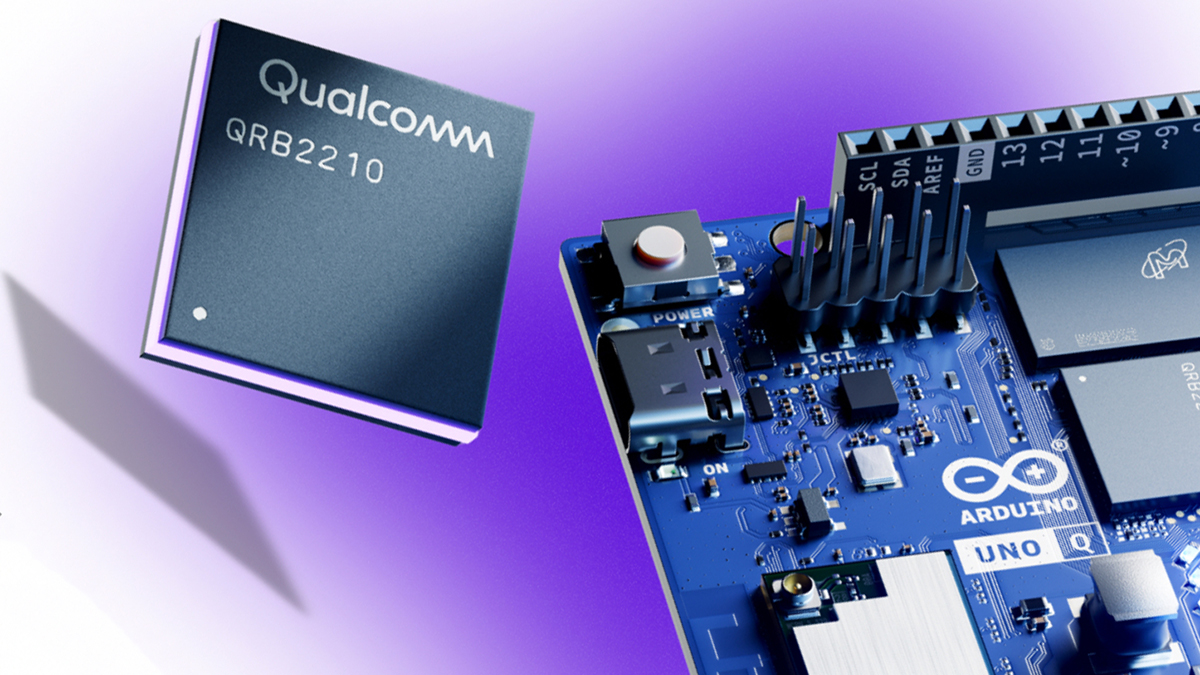

Qualcomm Acquires Arduino: Enterprise Silicon Meets the Maker Movement

In a move nobody saw coming, Qualcomm just acquired Arduino—the open-source hardware platform that taught 33 million engineers how to build embedded systems.

This is enterprise-grade edge computing colliding with the scrappy maker community that's been prototyping the future for 20 years. And the first product proves this isn't just a corporate acquisition—it's a genuine collaboration.

The Arduino UNO Q debuts with Qualcomm's Dragonwing processor featuring a "dual brain" design:

- Linux-based computing for AI workloads and complex processing

- Real-time microcontroller for precise hardware control

- Arduino App Lab connecting real-time OS, Linux, Python, and AI workflows

- Full Arduino IDE compatibility

This is exactly what industrial edge applications have needed: the processing power to run AI models locally, combined with the real-time reliability to control physical systems.

Why This Matters:

Arduino has always been the gateway for hardware prototyping—reading sensors, testing conveyor controls, building proof-of-concept HMIs. But traditional Arduino boards were too limited for production AI workloads.

That's changing. Qualcomm brings enterprise-grade processing, on-device AI, and 5G connectivity. Arduino brings 33 million developers, an open ecosystem, and the trust factor that enterprise vendors struggle to earn.

The result? Faster prototyping of edge AI solutions on familiar hardware, lower barriers to advanced analytics at the edge, and a clear migration path from proof-of-concept to production.

The Bigger Play:

This is Qualcomm's third edge computing acquisition after Foundries.io and Edge Impulse. They're assembling a complete stack for edge AI—from silicon to development tools to device management.

Arduino CEO Fabio Violante promises to "supercharge our commitment to accessibility and innovation," while co-founder Massimo Banzi pledges to stay "true to what has always mattered most to us."

Time will tell if that balance holds. But Arduino boards with legitimate AI processing power, industrial-grade reliability, and the same accessible development environment? That's genuinely exciting.

The future of edge computing might just look like an Arduino—only smarter, faster, and ready for the factory floor.

👉 Read about the Qualcomm-Arduino acquisition

Learning Lens

Missed the RESTful API for MCP Workshop? We’ve got you covered.

If you couldn’t make it to last week’s live session, now’s your chance to catch up — and save big. The recording of our RESTful API for MCP Workshop is now available, covering everything you need to start building API endpoints that plug directly into the Model Context Protocol ecosystem.

You’ll learn how to:

-

Design REST endpoints for seamless MCP integration

-

Structure payloads and responses that “speak” MCP

-

Validate and test your APIs for real-world interoperability

Until October 17, you can grab the full recording for 51% off using code RESTAPI4MCP — or skip the typing and use the direct link below.

👉 Get the recording + discount

Why it matters: The future of interoperability is here, and REST APIs are still its backbone. Mastering how to make them MCP-ready will future-proof your architecture and your career.

Byte-Sized Brilliance

The First Industrial Robot Was Sold at a Massive Loss

When Unimation built the first Unimate robot in 1961, it cost $65,000 to produce—but they sold it to General Motors for just $18,000. That's a loss of over 70% per unit.

Why? Because George Devol and Joseph Engelberger weren't just selling a product—they were selling a future. They knew that if they could prove the concept worked in a real factory, the orders would follow.

They were right. General Motors installed 66 more Unimates, Ford got interested, and the industrial robotics industry was born. By 1966, 450 Unimate robots were operating across the United States, and the company was licensing technology to manufacturers in Europe and Japan.

Sixty-plus years later, over 4.2 million industrial robots are at work worldwide, transforming everything from automotive assembly to pharmaceutical packaging.

Sometimes, changing the world means betting on a future nobody else can see yet—even if it costs you in the short term. That first $47,000 loss per robot? It bought an entire industry.

We Value your Feedback.

Click on the link below to provide us with your thoughts.

|

|

|

|

|

|

Responses